Difference between revisions of "Production Management"

(Created page with "{{BackTo|User Guide}} {{ManualDoc:SectionProduction Management(Openbravo Admin)}} ==== Transactions ==== {{ManualDoc:SectionProduction Management Transactions(Openbravo Adm...") |

(→Analysis Tools) |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 4: | Line 4: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==== Analysis Tools ==== | ==== Analysis Tools ==== | ||

{{ManualDoc:SectionProduction Management Analysis Tools(Openbravo Admin)}} | {{ManualDoc:SectionProduction Management Analysis Tools(Openbravo Admin)}} | ||

| − | |||

| − | |||

*[[Pending Work Requirement | Pending Work Requirement]] | *[[Pending Work Requirement | Pending Work Requirement]] | ||

*[[Production Cost Report | Production Cost Report]] | *[[Production Cost Report | Production Cost Report]] | ||

| + | *[[Production Run Status Report | Production Run Status Report]] | ||

| + | *[[Standard Costs Report | Standard Costs Report]] | ||

| + | |||

==== Setup ==== | ==== Setup ==== | ||

{{ManualDoc:SectionProduction Management Setup(Openbravo Admin)}} | {{ManualDoc:SectionProduction Management Setup(Openbravo Admin)}} | ||

| − | |||

| − | |||

| − | |||

*[[Activity | Activity]] | *[[Activity | Activity]] | ||

| − | *[[ | + | *[[Indirect Cost | Indirect Cost]] |

| + | *[[Machine | Machine]] | ||

*[[Machine Category | Machine Category]] | *[[Machine Category | Machine Category]] | ||

| − | *[[ | + | *[[Maintenance Task | Maintenance Task]] |

*[[Manufacturing Cost Center | Manufacturing Cost Center]] | *[[Manufacturing Cost Center | Manufacturing Cost Center]] | ||

*[[Periodic Quality Control | Periodic Quality Control]] | *[[Periodic Quality Control | Periodic Quality Control]] | ||

| + | *[[Process Plan | Process Plan]] | ||

*[[Quality Control Point | Quality Control Point]] | *[[Quality Control Point | Quality Control Point]] | ||

| + | *[[Section | Section]] | ||

| + | *[[Toolset | Toolset]] | ||

| + | *[[Work Center | Work Center]] | ||

*[[Work Incidence | Work Incidence]] | *[[Work Incidence | Work Incidence]] | ||

| − | *[[Maintenance | + | |

| − | *[[ | + | ==== Transactions ==== |

| + | {{ManualDoc:SectionProduction Management Transactions(Openbravo Admin)}} | ||

| + | |||

| + | *[[Calculate Standard Costs | Calculate Standard Costs]] | ||

| + | *[[Insert Maintenances | Insert Maintenances]] | ||

| + | *[[Internal Consumption | Internal Consumption]] | ||

| + | *[[Maintenance Order | Maintenance Order]] | ||

| + | *[[Maintenance Plan | Maintenance Plan]] | ||

| + | *[[Periodic Quality Control Data | Periodic Quality Control Data]] | ||

| + | *[[Production Run | Production Run]] | ||

| + | *[[Quality Control Report | Quality Control Report]] | ||

| + | *[[Work Effort | Work Effort]] | ||

| + | *[[Work Requirement | Work Requirement]] | ||

Latest revision as of 14:34, 19 November 2021

| Back to User Guide |

Contents

Introduction

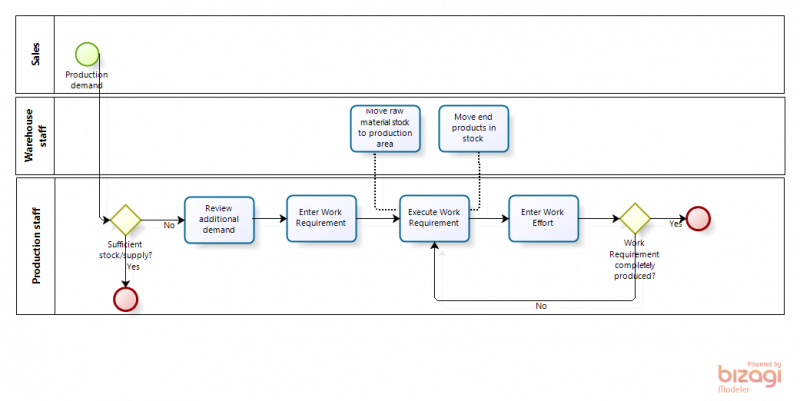

In Production Management the process of producing products from raw material is managed. The production process itself, as well as monitoring the quality of produced products, the maintenance of the machine used in production and the cost management for raw material and end products in managed.

Production Management

The main documents to manage the production process are:

- the Process Plan

- the Work Requirement

- the Work Effort

Configuration

Apart from the set up screens in the Production module, additional set ups are required.

For Production there are different products that are set up:

- Raw material used in production

- the Production checkbox is selected to indicate that the product is used for production

- the process plan is selected

- the Production checkbox is selected to indicate that the product is used for production

- Finished products produced in production

- the Production checkbox is selected to indicate the product is produced in production

- the process plan is selected

- the default storage bin that is used for the product is defined in the Manufacturing tab

- the Production checkbox is selected to indicate the product is produced in production

- based on cost calculations a "theoretical" standard cost can be determined for the finished product

- a safety stock level is determined and entered for the product

Any semi finished products are created directly in the process plan by copying the information of a raw material product used in the operation. Once created, the default storage bin is defined in the Manufacturing tab.

For more information about the configuration of products, please refer to the Product section.

Also Business Partners are configured for production:

In the Employee tab any employees that are involved in the production process have the operator checkbox selected.

For more information about the configuration of business partners, please refer to the Business Partner section.

Work Efforts can be posted to the General Ledger Journal. In order to facilitate the posting, the MaterialMgmtProductionTransaction table is activated in the Active Tables tab of the General Ledger configuration.

Execution

Sales staff enter Sales Order for the product with the quantity required and the date by when it needs to be delivered. If the product is not in stock, it needs to be produced.

Also if the stock level is below the safety stock level, products have to be produced.

The information about the demand from sales orders and safety stock is handled in 2 ways:

- automatically in MRP

- manually by a production manager

Ideally the information is handled by MRP. If not, a production manager reviews if production of the product is required by reviewing the total demand:

- the outstanding sales orders

- the safety stock level

and compare it with the total supply:

- the stock level

- scheduled Work Requirements

If the demand is higher than the supply, or the dates of scheduled Work Requirements are not matching the dates of the outstanding sales orders, the product needs to be produced and a production manager executes:

- review of the stock of the raw material. If needed the raw material will be requested used the procurement management process.

- entry of the Work Requirement for the required quantity with the required quantity and the planned date

- generate Work Efforts from the Work Requirement.

The staff responsible for executing the production can see on the Production Run Status Report what production has to be executed.

At the end of each shift, the production managers enter the information of what is produced in the Production Run screen.

Finance staff can calculate the actual cost of the production for the product.

Relationship with other areas

Production Management interacts with the following modules:

- Procurement Management: raw material required for use in production is bought using the Procure to Pay process

- Sales Management: demand for the products that are produced are generated through the Order to Cash process

- Warehouse Management:

- raw material is taken from the warehouse to be used in production

- end products that come out of production are put into stock

- MRP: Work Requirements can be a result of MRP

- Financial Management: Cost related to Production is calculated for finance.

Application Menu

Please find below detailed descriptions of all windows and report of the Production Management application area.

Analysis Tools

.

Setup

The following screens are used to set up the components used in the production process:

- Activity

- Indirect Cost

- Machine

- Machine Category

- Maintenance Task

- Manufacturing Cost Center

- Periodic Quality Control

- Process Plan

- Quality Control Point

- Section

- Toolset

- Work Center

- Work Incidence

Transactions

.

- Calculate Standard Costs

- Insert Maintenances

- Internal Consumption

- Maintenance Order

- Maintenance Plan

- Periodic Quality Control Data

- Production Run

- Quality Control Report

- Work Effort

- Work Requirement

| Back to User Guide |