Machine

| Back to Production Management |

Introduction

Create machines to be used in production.

In this screen all the different machines used in production are set up.

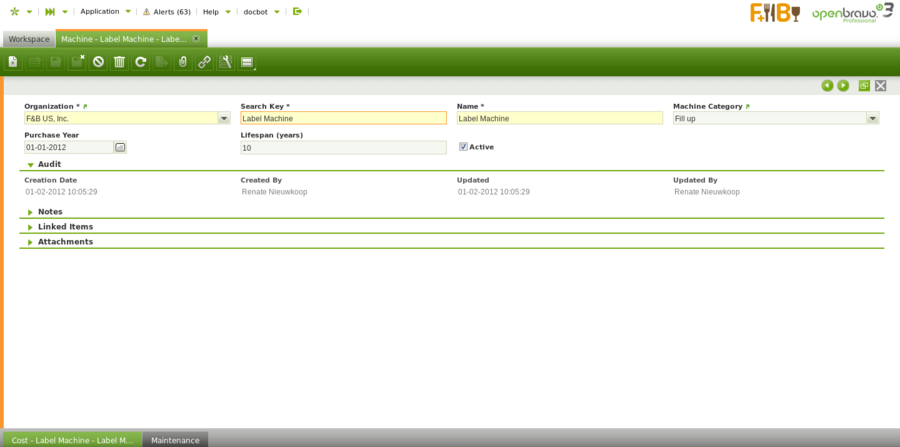

Machine

Add machines to be used in production processes.

- Machine Category: which grouping of machines this particular machine belongs to

- Purchase Year: the date of purchase of the machine

- Lifespan: the estimated time that the machine can be used for the production process

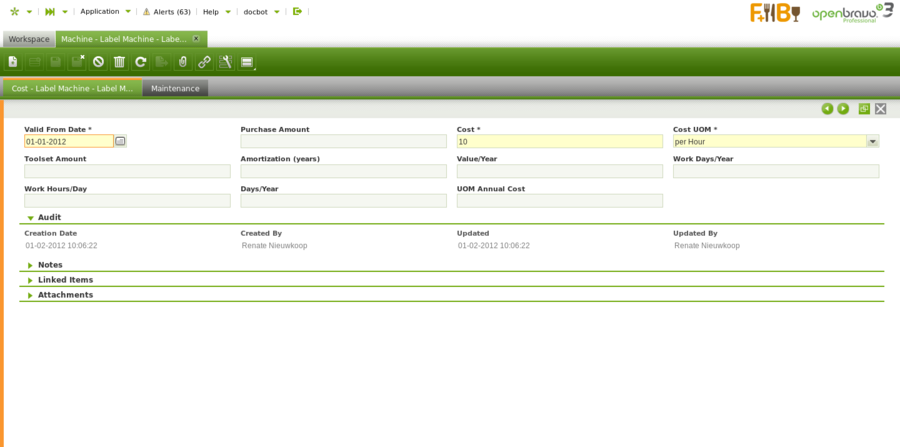

Cost

Set the full cost of a related machine.

In the Cost tab, all cost and amortization information is entered:

- Valid from Date: start date for the amortization

- Purchase Amount: the amount that is paid for the machine

- Cost: cost per UOM automatically populated after the above information about the machine is filled out, based on the calculation: Value/Year / UOM Annual Cost. In the above example this is 3750 / 2350 = 1.60.

- Cost UOM: indication of how the cost should be calculated, per hour, per produced units, etc.

- Toolset Amount: extra amount for the machine, for example for components

- Amortization: number of years in which the amortization for the machine will take place

- Value/Year: amortization amount per year, based on the calculation: (Purchase Amount + Toolset Amount) / Amortization. In the above example this is (10,000 + 5,000) / 4 = 15,000 / 4 = 3,750. The value is populated when the amount of year of amortization is entered.

- Work Days/Year: amount of days per year that the machine is used

- Work Hours/Day: number of hours per day that the machine is used

- Idle Time/Year: number of hours that the machine is not working in a year, for example because it is in maintenance.

- UOM Annual Cost: Populated field based on the calculation: (Work Days/Year x Work Hours/Day) - Idle Time/Year. In the above example this is (300 x 8) - 50 = 2400 - 50 = 2350.

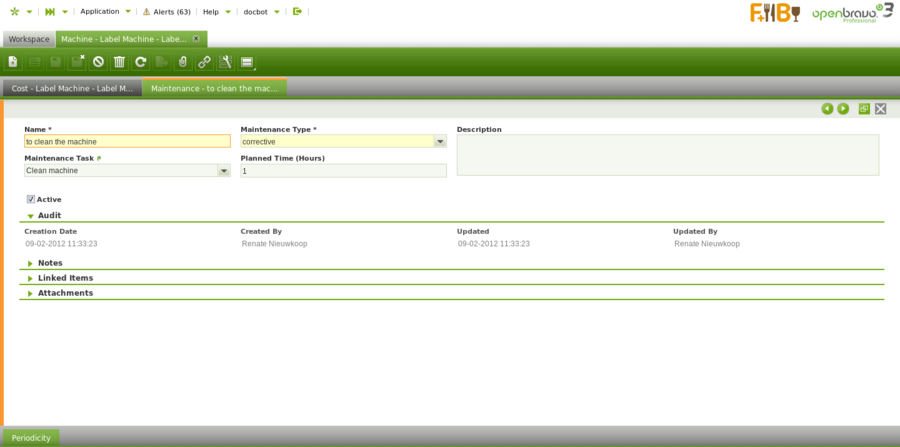

Maintenance

Define maintenance types needed for a specific machine.

Any maintenance information required for the machine is entered in this tab.

- Maintenance Type: to indicate the nature of the maintenance:

- preventive

- corrective

- corrective(urgent)

- planned time: to indicate how long it takes to execute the maintenance task.

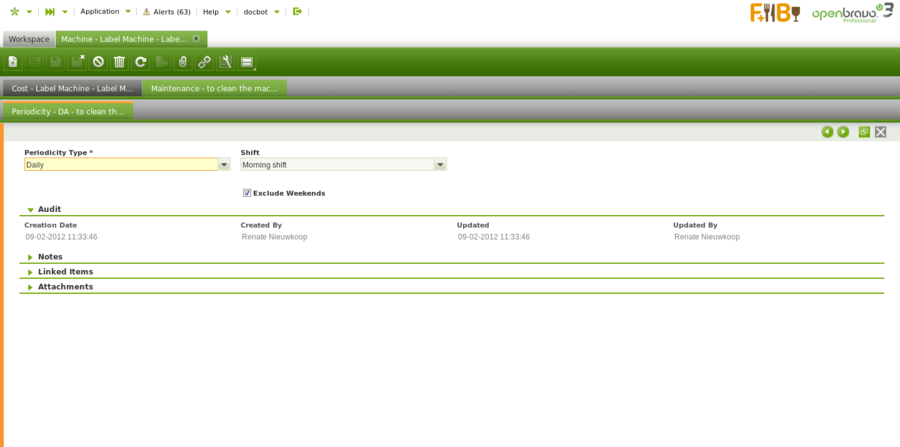

Periodicity

Add timing intervals to schedule and complete a specified maintenance.

This tab is to define with which frequency and during which shift the maintenance is scheduled to take place:

- Periodicity Type:

- Daily

- Bi-monthly: the Starting Day field appears to define when the first maintenance is scheduled

- Half-yearly: the Starting Day field appears to define when the first maintenance is scheduled

- Monthly: the Day of the Month field appears to define which day of the month the maintenance is scheduled

- Quarterly: the Starting Day field appears to define when the first maintenance is scheduled

- Weekly: the Weekday field appears to define which day of the week the maintenance is scheduled

Full list of Machine window fields and their descriptions is available in the Machine Screen Reference.

| Back to Production Management |