How to Manage Attributes And Attribute Sets

Contents

Objective

Attributes and attribute sets are used by companies to manage warehouses efficiently as attributes are additional information of each stocked product.

There are many scenarios where companies may use product attributes:

- Companies have hundreds of items stocked, and the only difference between them is its size, color, image, etc. however all of them have same price.

- Additional data for every product must be recorded, for instance expiration data or consumption data of products.

- Sequential Serial number is needed for production matters.

- Lots must be recorded, that is often the case in food processing industry.

There are two types of product attributes, attributes can be instance attribute or not. The difference between them is that an instance attribute implies to track the item on the warehouse.

The attribute "Color" is not an instance attribute because:

- a company can have two red shirts on the warehouse and then buy another red shirt. It is not important to know which one has been bought first or later, therefore color is not an instance attribute.

A Lot number is an instance attribute because:

- if a company has a piece of meat in stock, and buy another piece of meat, it is necessary to identify each piece of meat separately, it is necessary to know when each piece was bought and when it will expire, therefore a lot is an instance attribute.

The use of proper product attributes help companies to manage their stock and therefore their warehouses efficiently.

This article is going to focus on the first attribute type, non instance attributes.

Recommended articles

Using attributes for warehouse management requires a clear understanding of what attributes and attribute sets are.

It is also important to understand what warehouse management means in Openbravo, and take a look at how warehouses are structured with storage bins.

Finally it is important to know how Lot number sequence and serial number sequences can be configured in Openbravo. The way to make those work will be explained in a different how to article.

Execution steps

The company in this example needs to follow below steps:

- properly define attributes and an attribute set

- configure a product by using the previously created attribute set

- and finally, execute some transactions with the product.

Attribute & Attribute Set creation

In Openbravo, the company in this example sells clothes, therefore needs to manage and sells shirts.

Shirts can be white, red or green and can have small, medium or large size.

The price for all shirts is the same, however it is important to know how many red, white and green shirts are stocked at every moment and the size of each of them.

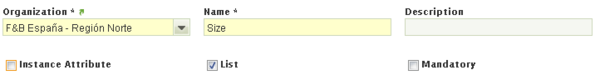

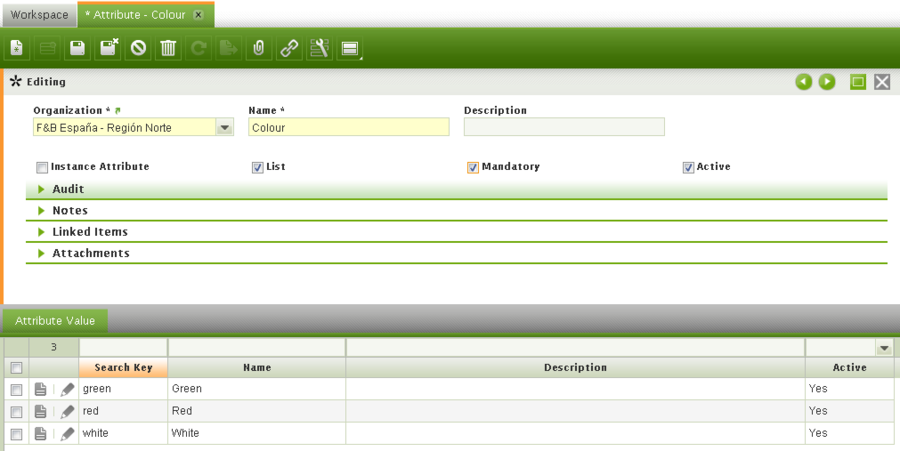

The company in this example needs to create "Color" attribute, this attribute has three possible values:

- red

- white

- and green.

Some meaningful fields to take into account while creating "Color" attribute are:

- Instance attribute, as explained above this is not an instance attribute

- List, this one defines if the attribute has a free value attributes list or not. If it is checked the values of the attribute must be one of the defined Attribute Values.

- Mandatory, define if an attribute will be mandatory or not.

- If an attribute is set as "Mandatory" an attribute value must be informed every time the product is included in a transaction, besides the input field "Attribute" will be shown with yellow background on every transaction.

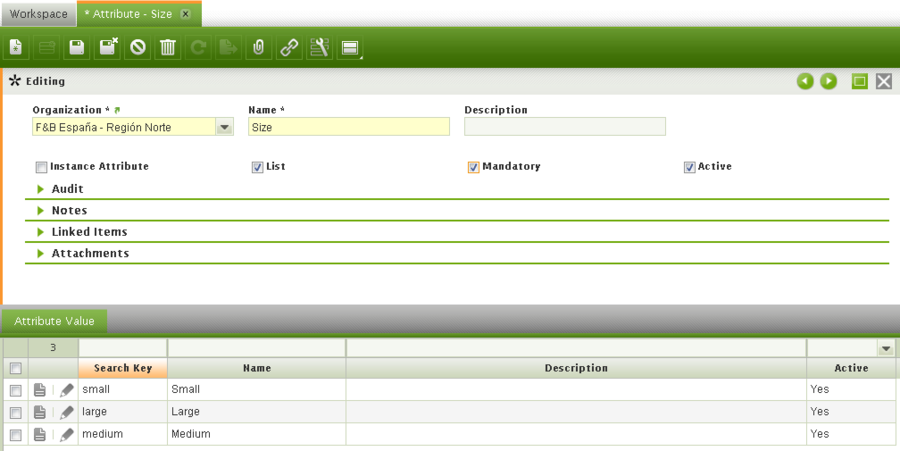

The company in this example creates same way "Size" attribute with three possible values:

- small

- medium

- and large.

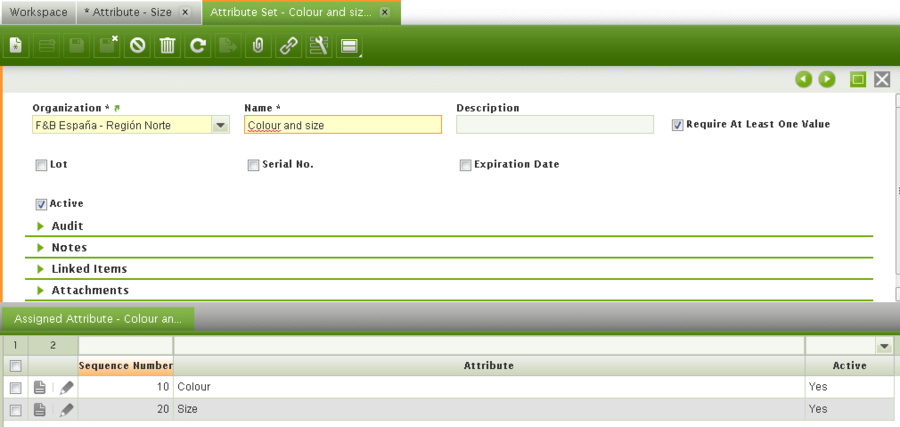

As last configuration step an attribute set needs to be be created.

An attribute set is a combination of attributes, once created can be assigned to the products, therefore every time the product is managed, that means purchased, stocked or sold, Openbravo will ask for every attribute value of the attribute set.

An attribute set can include just one or a set of attributes, furthermore an attribute set could also include serial numbers and lots, but that is not going to be explained in this article.

A meaningful field to notice is:

- Expiration date. This feature is usually related to attribute sets which includes lots and/or serial numbers for which it is required to manage a given number of guaranteed days. Therefore, if this field is checked for an attribute set, a date is required to be entered every time the attribute set is used for a product. This feature will be explained in a separate How To.

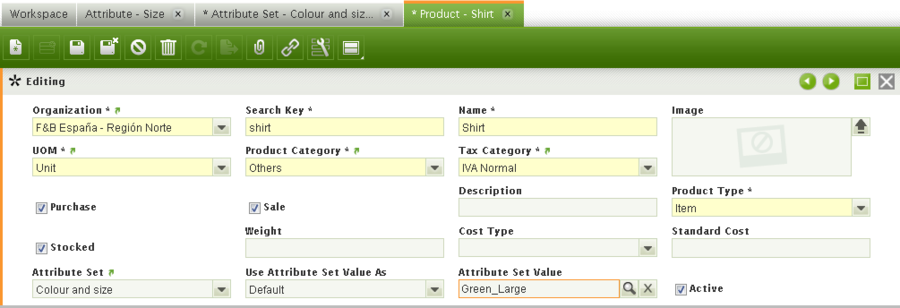

Product creation

At this point, the company in this example can create the products required and configure them with the above created attribute set.

There are some meaningful fields to take into account while creating a product with an attribute set:

- Attribute set, a product can only have an attribute set assigned.

- Use attribute set value as, if "Default" value is selected, the values entered in the next field will be the ones automatically shown by default. Default values can always be changed by the user.

This field has other options to choose which are explained in the Product window. - Attribute set value, a defined set of by default attribute values for the product, which can be entered by just selecting them by pressing the "magnifying glass" icon.

Product management

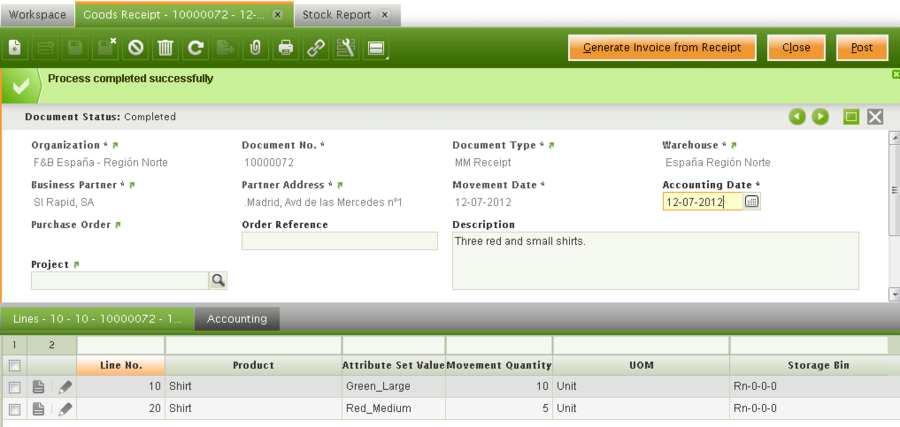

The company in this example purchases and receives 10 Green-Large shirts and 5 Red-Medium shirts.

Goods Receipts window allows the company to receipt the purchased shirts:

It is mandatory to register the Color and the Size of each product received and therefore good receipt line.

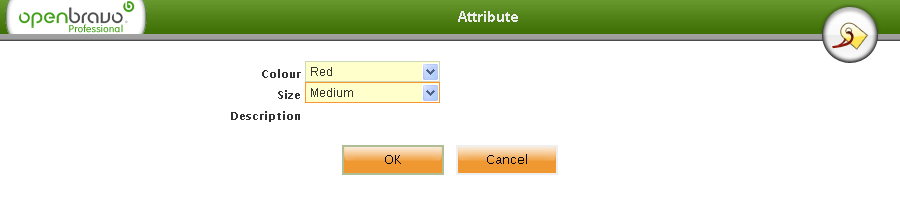

Although Green and Large values are shown by default, as those are the default attribute set values, both values can be changed to any other value already created of this attribute set, for instance, "Red" and "Medium".

The "Attribute" window is used to select the attribute values for incoming products. This window is launched by pressing the "magnifying glass" icon of the product field located in the goods receipt line.

It is important to remark that it is not possible to add new values to the attributes from this window, but just select previously created ones.

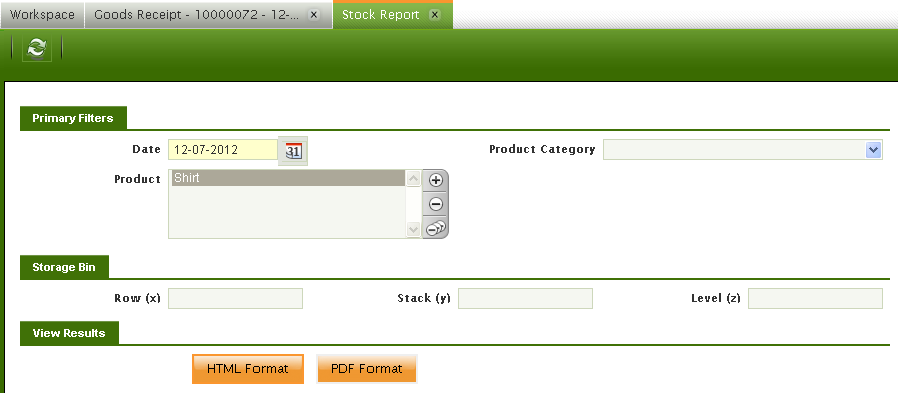

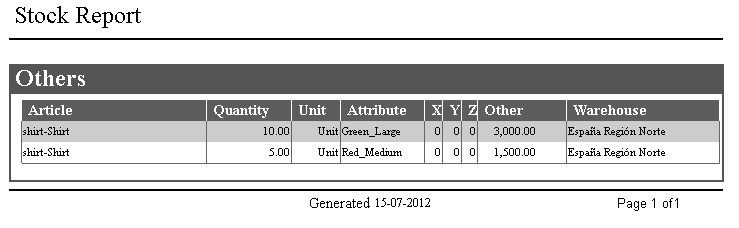

As 15 shirts have been received, those ones will be shown in the Stock Report.

The Stock Report is used to check goods quantities as well as goods location at a certain date.

Although there are 15 shirts, the report properly shows that there are 10 Green-Large shirts and 5 Red-Medium shirts in a given warehouse and storage bins.

The process is similar while shipping products with attributes or while moving products with attributes from one warehouse to another, as it is only possible to ship or move a product having a certain attribute set value if there is stock of that product in the warehouse.

The product selector help us to know which is the product quantity on hand for a product having a given attribute set while creating a goods shipment line or a goods movement line.

Results

This completes the Attribute and Attribute set creation and its use. As a result:

- Attributes have been created.

- Attribute set has been created.

- A Product using this attribute set has been created.

- A Good Receipt has been created using the previously created product.

- Stock report has been checked.