Process Plan

| Back to Production Management |

Contents

Introduction

Define the steps and processes to be completed for an intermediate or finished good, taking into account available resources.

TBD

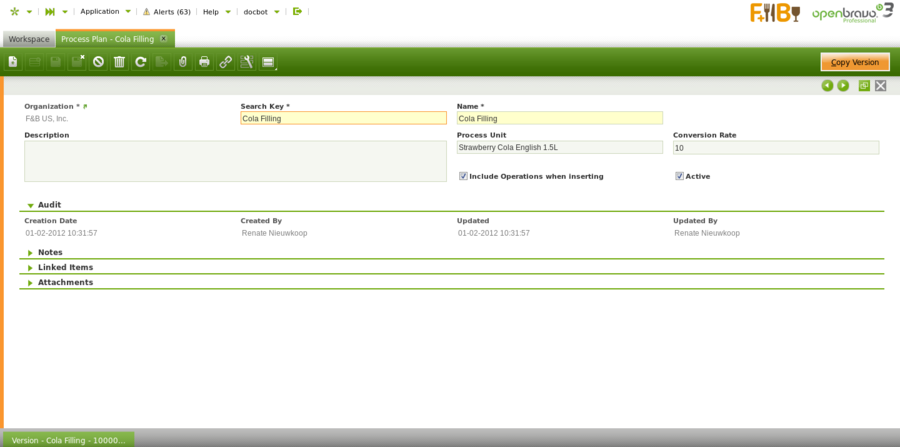

Process Plan

Create production process models.

A key document in production management is the Process Plan. Each product that is produced has a process plan to define the exact operations and the input and output for each operation. Based on the effective use of raw material and machines a batch size (conversion rate) is used for the production of each product.

- Organization: organization of the process plan

- Search Key: abbreviation or full name used to easily filter the record

- Name: name of the process plan

- Description: note field

- Process Unit: the outcome of the production process

- Conversion rate: batch size of the produced product

- Include Phases when inserting checkbox: when the checkbox is selected: in the Work Requirement, when the information from the process plan is copied, the operations and the products are included.

- Copy version button: to copy the content of another version of the same process plan

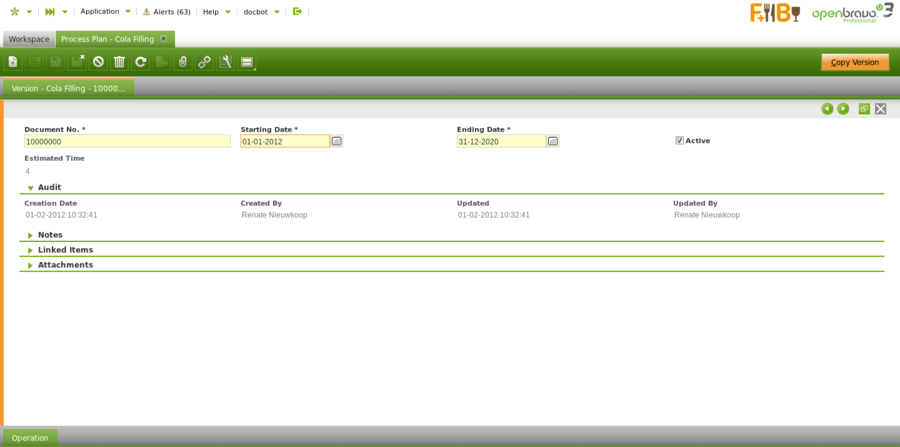

Version

Create process plans valid for a specified time period.

Changes may be needed for a process plan. To make sure the history of all changes is kept, different versions of the process plan are created. The copy version button is used to duplicate existing versions of the same process plan for re-use. The copied version is updated with the required changes.

Each version has a starting date and an ending date.

The estimated time field is populated with the value of the accumulation of the estimated time of all the operations in the process plan. The information is updated by the application each time an estimated time is entered and saved on an operation.

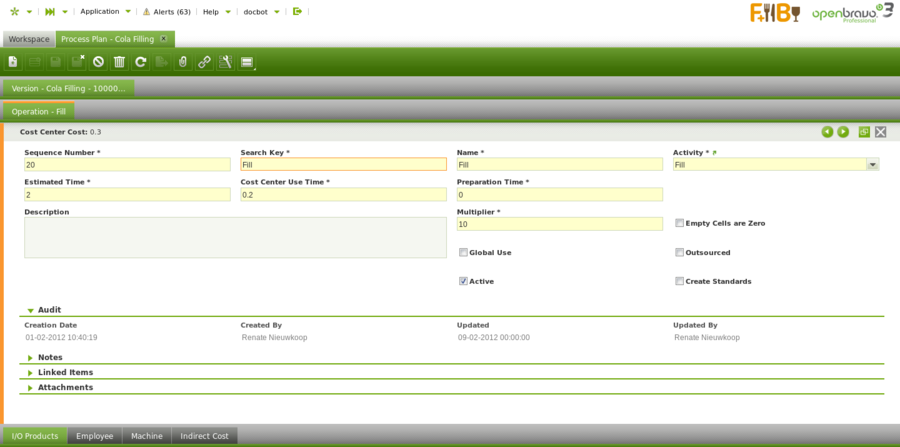

Operation

Add processes to be performed for a specified process plan.

Each stage of the production process is defined as an operation.

Name: name of the operation

Activity: activity that is executed during the operation

Estimated Time: information entered by the user to indicate what the

estimated time in hours is to execute the operation.

Cost Center Use Time: estimation of how long the cost center will be used

during the operation

Preparation Time: time indication of any preparations needed for the

operations

Description: note field

Multiplier: indication of how many times the operation has to be executed in one production run

Empty cells are zero checkbox: selection has the result that when the Work Requirement inserts the process plan information, the quantities on the products are left zero, so they can be entered manually.

Global use checkbox: when selected the application populates the product in the global use tab of the Work Effort when the create standards process is executed. When the work effort is validated, the application divides the entries in the global use tab between all production runs that use this product. It is inserted as an additional P- in order to be included in costs calculations.

Outsourced checkbox: indication of the operation being executed by a third party

Create Standards checkbox: the process plan is used to automatically generate information about operations and products in a work requirement. From the work requirement, work efforts can be created to document the work executed in production. In order to know what products were involved in the work effort, the create standards process is executed on the work effort. When the Create Standards checkbox is selected, at the moment that work efforts are created from the work requirement, also the create standard process is executed. By default the checkbox is not selected.

Note:

The Create Standards process will only complete successfully if there is sufficient stock for the used products (P-) of the operation. The stock has to be in a warehouse that is related to the organization of the Work Requirement.

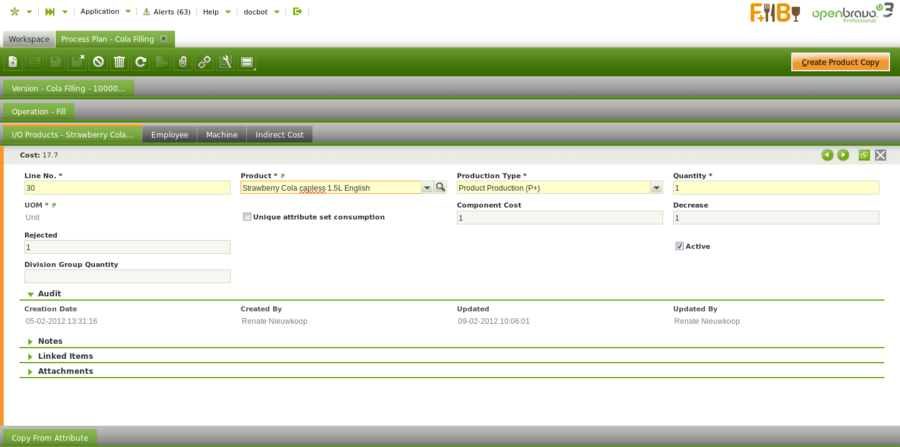

I/O Products

Define input and output products taking part in a specified process.

For each operation, the products that are used (P-) and the products that are produced (P+) are defined.

The fields that are displayed depend on the selected Product Type.

Product: product used in the operation. Only products that have the production checkbox selected in the product screen, appear in the list of products.

Product Type: indication of whether the product is used (P-) or produced (P+) during the operation

Quantity: quantity of the product

UOM: unit of measure of the product

Unique attribute set consumption checkbox: field that only appears for product used (P-). When selected, the application will select stock with the same attribute only. For example if the product has different lot numbers, all stock that is used during the operations will be taken from the same lot.

Component Cost: field that only appears on produced (P+) components.

The input is a factor used to distribute the cost when a Operation has more than one P+ product.

Example:

An operation consumes 10 (P-) A and produces 5 (P+) B and 10 (P+) C.

The cost process calculates a total cost of 15USD for the operation (including cost center related costs). That cost has to be distributed between P+ B and P+ C. If both B and C have a Component Cost of 1 the cost will be equally distributed between B and C. Resulting in a cost of 7.5USD/5 = 1.5USD/unit of B and 7.5USD/10 = 0.75$/unit of C.

If B has a Component Cost of 1 and C of 2, the cost assigned to C has to be twice the cost of B. 5USD are assigned to B and 10USD to C resulting in a cost of 5USD/5 = 1USD/unit of B and 10USD/10 = 1USD/unit of C.

The way to calculate the particular factor of any P+ is to divide the component cost of the particular P+ by the sum of the Component Costs (CC) of all the P+ products.

Decrease: information only field

Rejected: information only field

Division group quantity: field that only appears on produced (P+) components. The value entered is the quantity that is produced with the same attribute value. For example if the attribute is lot number or serial number, the number entered in this field indicates how many products will get the same lot number or serial number during production. During production the following attributes are automatically assigned to products in production:

- expiration date

- serial number

- lot number

Create Product copy button: as indicated in the product configuration, semi finished products can be created by copying the product that is used to produce this particular semi finished product. This functionality can also be used to create other raw material products, in which case the selected Production Type is product used (P-). When copying the information, the search key and name are suggested in the format [original product][operation name][operation line number], but can be overwritten with a different value. Any attributes related to the original product can be copied also.

Note:

Any changes to the automatically created product, such as unit of measure or cost type, can be updated in the Product screen.

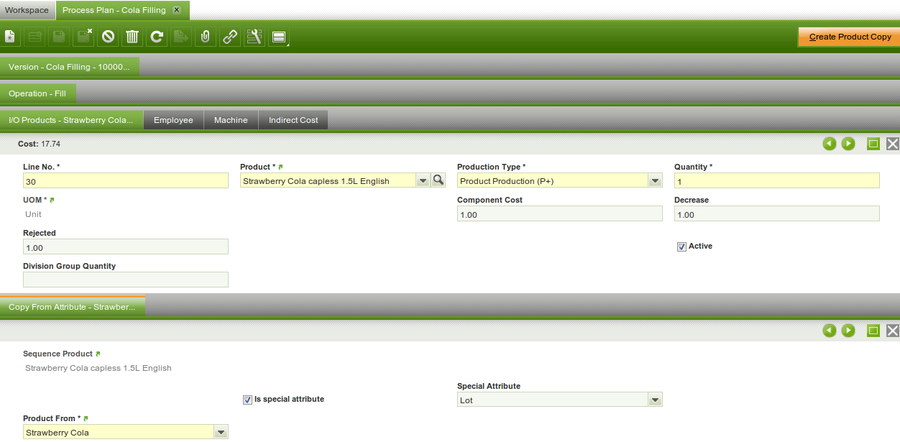

Copy From Attribute

Define the relation between attributes to be copied.

The Copy From Attribute tab is used for products of the production type P+. The tab is used to enter the different attributes to be inheritted from different P-'s, that are used to produce the P+. This means that only P-'s used in this operation can be selected to be copied from. In the case that the P+ is created by copying a product, if the attributes were copied during the creation, the system populates the information in this tab:

- Is special attribute checkbox: used for special attributes, which are lot, serial number and expiration date. When not selected, a regular attribute is selected to be copied.

Note: When attributes are copied over to a different product, the product that the attribute is copied to has to be configured with that attribute also.

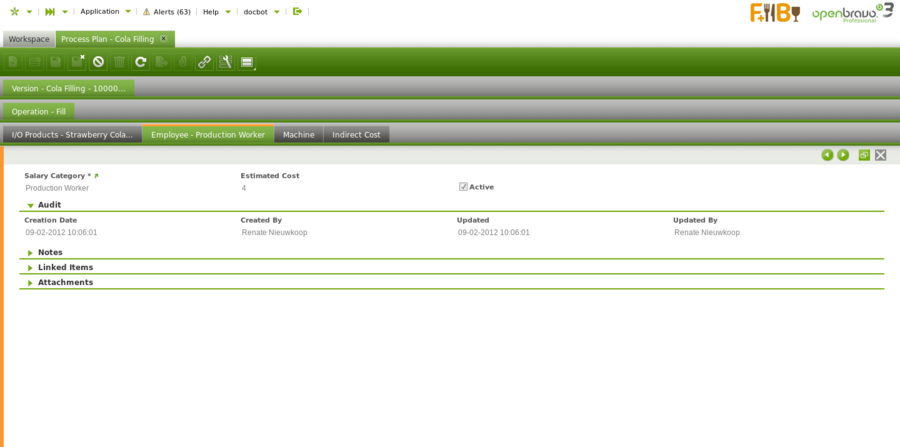

Employee

Define the employees that can perform a specified process.

The process to generate standard cost (theoretical) will populate the cost information in the Employee, Machine and Indirect Cost tabs. For details, please refer to the Calculate Standard Cost section. The information is needed for the theoretical cost calculation of the P+.

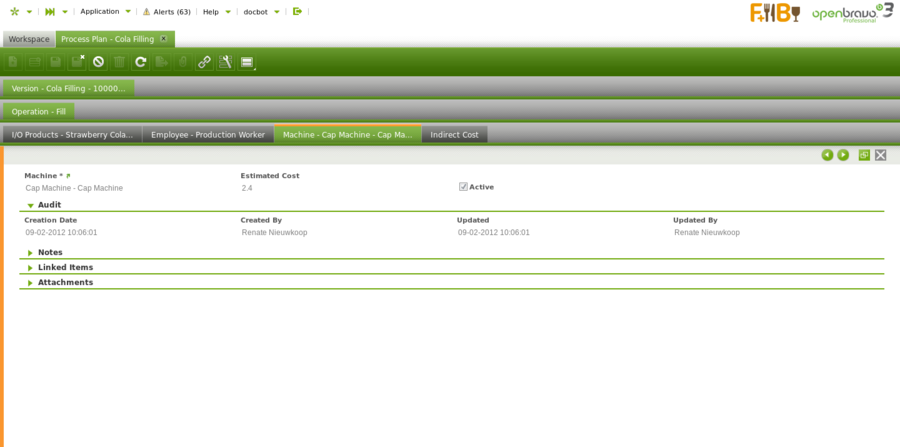

Machine

Define machines that are used for a specific process.

The process to generate standard cost (theoretical) will populate the cost information in the Employee, Machine and Indirect Cost tabs. For details, please refer to the Calculate Standard Cost section. The information is needed for the theoretical cost calculation of the P+.

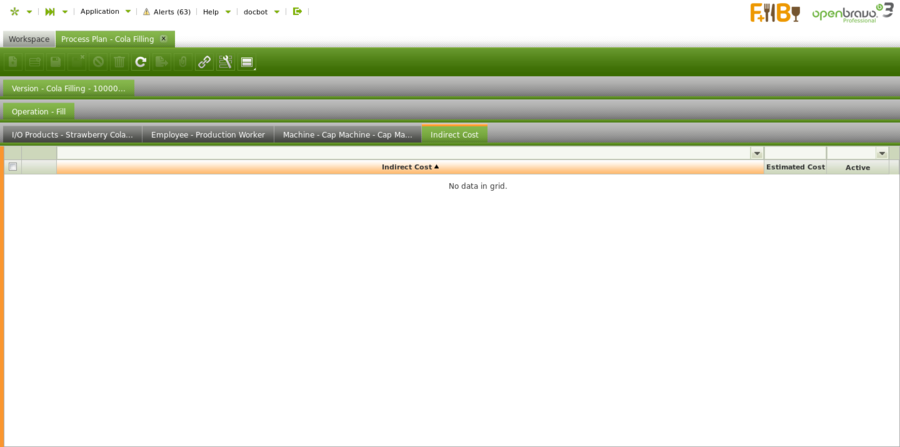

Indirect Cost

Define indirect costs related to a specified process.

The process to generate standard cost (theoretical) will populate the cost information in the Employee, Machine and Indirect Cost tabs. For details, please refer to the Calculate Standard Cost section. The information is needed for the theoretical cost calculation of the P+.

Full list of Process Plan window fields and their descriptions is available in the Process Plan Screen Reference.

| Back to Production Management |