Quality Control Point

| Back to Production Management |

Introduction

Define quality control check points to be used for testing the product quality at any point in the production process.

Quality Control Point is a point or stage of manufacturing where it is essential to control (reduce or eliminate) a risk to avoid downtime.

For example, checking the temperature of oil every three hours. There is the ability to set the frequency and list required tasks and accountable personnel.

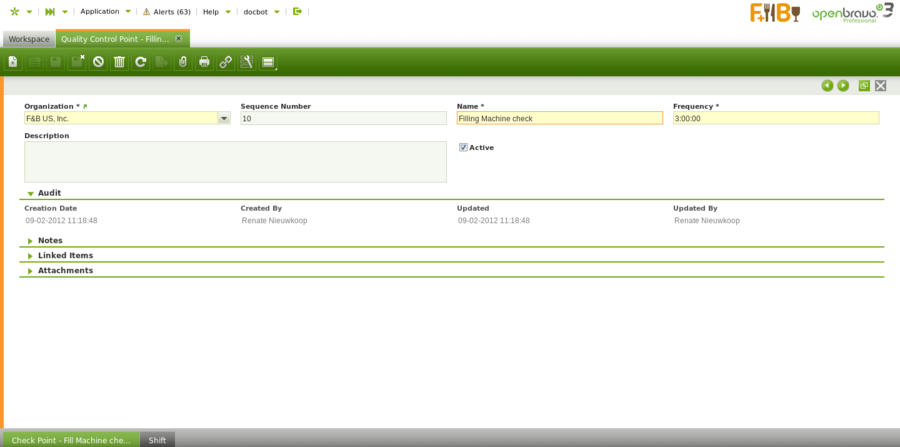

Check Point Set

Create check point sets and define tests frequencies.

- Frequency: the number of hours between checks

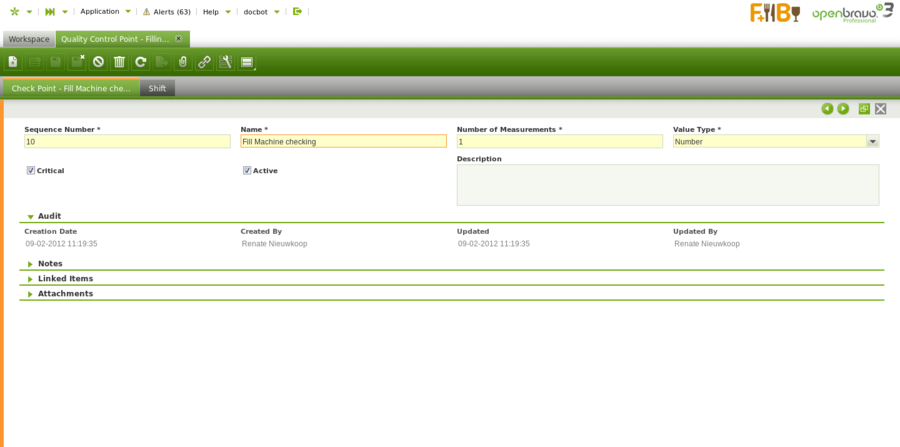

Check Point

Create check points for a related set.

- Name: the name of the exact control that is defined.

- Number of Measurements: the number of times this concrete control has to be executed. For example the number of times temperature needs to be meassured.

- Value: the type of value of the outcome of the check that is executed.

- Critical checkbox: information only field to indicate a check is critical.

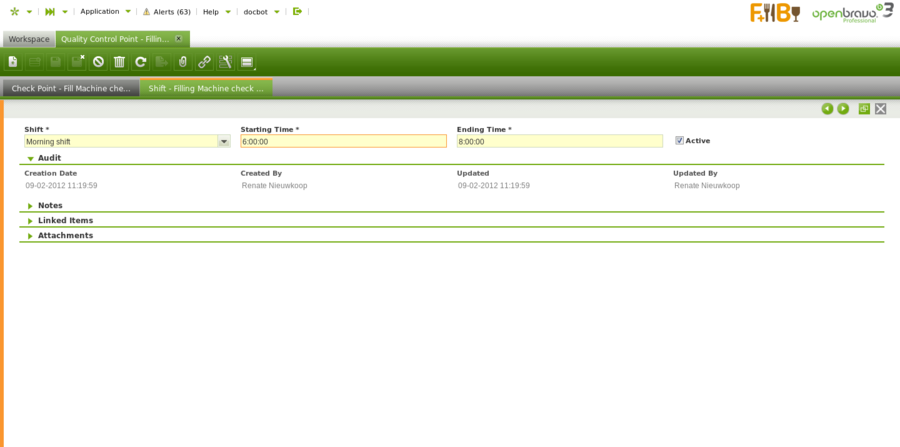

Shift

Define shifts when the tests for a related group will be performed.

The information in this tab is used for the automatic population of check point set information when the results are reported in the Quality Control Report. In the main section of the report the shift is selected.

The starting date in this set up is used for the automatic population of the time information of the Quality Control Report.

Full list of Quality Control Point window fields and their descriptions is available in the Quality Control Point Screen Reference.

| Back to Production Management |