Template:ManualDoc:T187

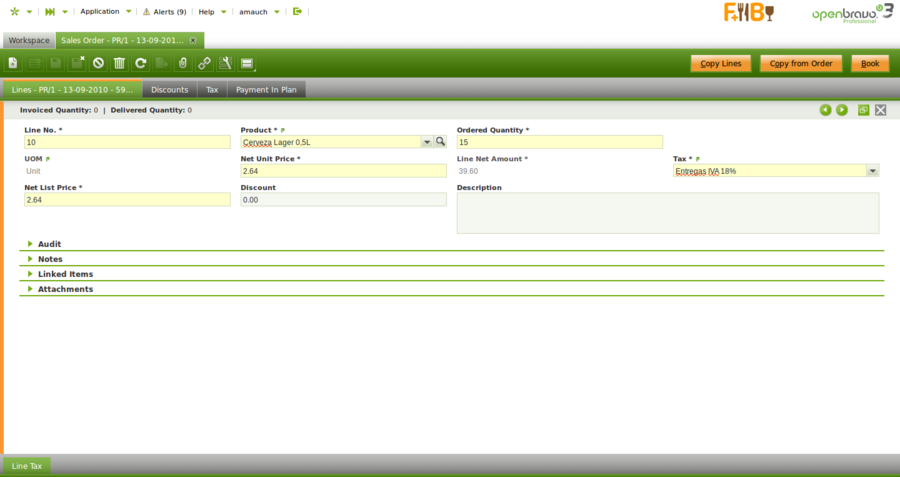

Lines tab lists each product ordered and its characteristics.

Fields to note:

- Ordered quantity, or Operative Quantity if the product has an alternative unit of measure (AUM) configured.

This is the quantity needed of the product/item - Product's UOM, or product's Alternative UOM depending on product configuration in regards to unit of measure.

- Attribute Set Value: field is displayed if the product in the line has attributes (color, size, serial number or several of them together etc).

- Discount: indicates the discount applied as a percentage of the List Price.

- Invoiced Quantity and Delivered Quantity: are shown on the Status Bar when the line with a product is saved and get updated when an invoice or shipment related to this line is issued.

- Warehouse Rule: Definition of a Warehouse Rule to be applied when the goods shipment is automatically generated. This rule overwrites any one defined in the warehouse. If no warehouse rule is defined in the sales order, the rule defined in warehouse is applied.

For additional information review Warehouse Rule Examples section below.

Explode button is shown when selecting a line with a non-stockable BOM product and the product has not already been exploded. When exploding a product, the bill of materials components the selected product consist of are shown in the order. Once you have explode it, you cannot comprime it. You should delete all the lines (first bill of materials components and then the BOM product), and insert again the non-stockable BOM product.

Book button completes the sales order when all the products are entered. If there are non-stocable BOM products and they have not been exploded, the Book process will explode them.

Close button actions closes an order, which implies that :

- no further actions can happen but to prepay that order if applicable, if a fully delivered sales order is closed

- ordered quantity changes to delivered quantity and no further actions can happen but to prepay that order, if a partially delivered sales order is closed

- ordered quantity changes to 0 and no further actions can happen, if a not delivered sales order is closed

Warehouse Rule implementation examples

Example 1 You have defined two on hand warehouses for an organization. Warehouse North (priority 10): Unique Attribute warehouse rule

- Storage bin N0: 45 uds

- Storage bin N1: 30 uds

Warehouse South (priority 20)

- Storage bin S0: 12 uds

- Storage bin S1: 65 uds

Create a sales order with quantity 60 and warehouse rule Unique Storage Bin. Book the sales order. Go to create shipments from order and select the newly created sales order. Process it and you will have a good shipment with 60uds taken from Warehouse South-Storage bin S1.

Example 2

You have defined two on hand warehouses for an organization.

Warehouse North (priority 10): Unique Attribute warehouse rule

- Storage bin N0:

- 10 uds lotA

- 20 uds lotB

- Storage bin N1:

- 15 uds lotA

- 15 uds lotB

Warehouse South (priority 20)

- Storage bin S0:

- 5 uds lotA

- 12 uds lotB

- Storage bin S1:

- 20 uds lotA

- 25 uds lotB

Note:lotA and lotB are instance attributes for the same product. Create a sales order with quantity 22. Complete the sales order. Go to "create shipments from order" and select the newly created sales order. Process it and you will have a good shipment with 2 lines:

- 10uds from Warehouse North - storage bin N0

- 12uds from Warehouse North - storage bin N1

Stock reservations

Sales Order lines can be reserved when the sales order is booked and is pending to deliver.

Fields to be noted:

- Stock Reservation: Defines if it desired to automatically reserve the sales order line when it is booked. Available values are:

- Manual: No reservation needs to be generated automatically. So when the order is booked you manually create the reservation

- Automatic: The reservation is automatically created and processed, reserving the available stock.

- Reservation Status: Defines whether the line is Fully Reserved or Partially Reserved or Not Reserved.

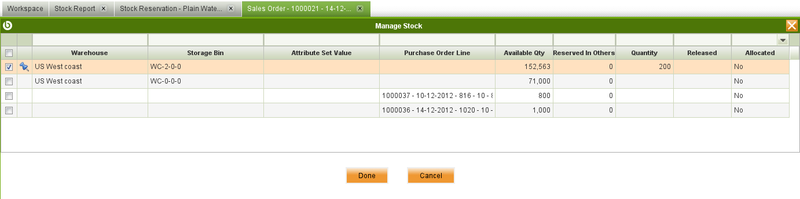

Manage Reservation pick and execute

Using the Manage Reservation button is possible to open a Pick and Execute window to create and modify reservation for the Sales Order Line. The grid shows all the available stock that can be delivered and the pending to receive purchase orders.

In the grid it is possible to select and set the desired quantity on any available stock. There are validations to avoid setting quantities higher than the available for the specific stock or than the ordered quantity. The Done button will create and process a reservation if none exists with the selected options, note that if the reservation does not exists and the Done button is pressed without selecting any stock or selecting a quantity below the ordered quantity, when the reservation is processed the system will reserve the remaining quantity with the available stock. If a reservation already exists the reserved stock will appear automatically selected and the Done button will update the reservation with the changes done. It is also possible to flag a stock as allocated.