Template:ManualDoc:T800110

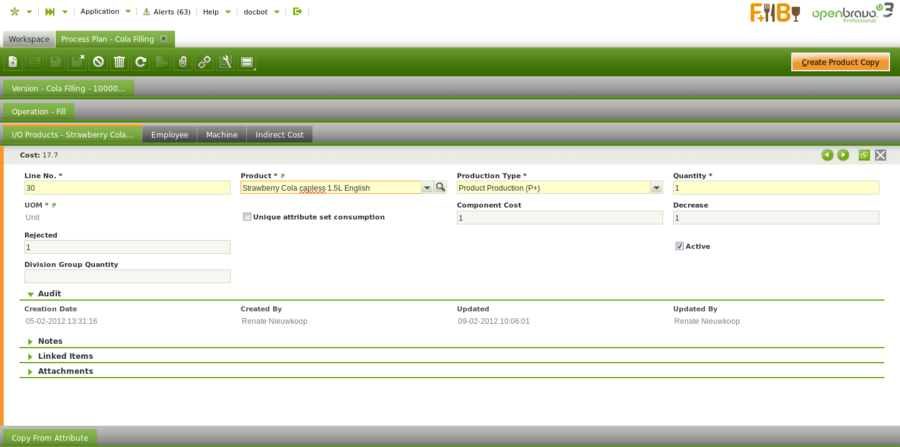

For each operation, the products that are used (P-) and the products that are produced (P+) are defined.

The fields that are displayed depend on the selected Product Type.

Product: product used in the operation. Only products that have the production checkbox selected in the product screen, appear in the list of products.

Product Type: indication of whether the product is used (P-) or produced (P+) during the operation

Quantity: quantity of the product

UOM: unit of measure of the product

Unique attribute set consumption checkbox: field that only appears for product used (P-). When selected, the application will select stock with the same attribute only. For example if the product has different lot numbers, all stock that is used during the operations will be taken from the same lot.

Component Cost: field that only appears on produced (P+) components.

The input is a factor used to distribute the cost when a Operation has more than one P+ product.

Example:

An operation consumes 10 (P-) A and produces 5 (P+) B and 10 (P+) C.

The cost process calculates a total cost of 15USD for the operation (including cost center related costs). That cost has to be distributed between P+ B and P+ C. If both B and C have a Component Cost of 1 the cost will be equally distributed between B and C. Resulting in a cost of 7.5USD/5 = 1.5USD/unit of B and 7.5USD/10 = 0.75$/unit of C.

If B has a Component Cost of 1 and C of 2, the cost assigned to C has to be twice the cost of B. 5USD are assigned to B and 10USD to C resulting in a cost of 5USD/5 = 1USD/unit of B and 10USD/10 = 1USD/unit of C.

The way to calculate the particular factor of any P+ is to divide the component cost of the particular P+ by the sum of the Component Costs (CC) of all the P+ products.

Decrease: information only field

Rejected: information only field

Division group quantity: field that only appears on produced (P+) components. The value entered is the quantity that is produced with the same attribute value. For example if the attribute is lot number or serial number, the number entered in this field indicates how many products will get the same lot number or serial number during production. During production the following attributes are automatically assigned to products in production:

- expiration date

- serial number

- lot number

Create Product copy button: as indicated in the product configuration, semi finished products can be created by copying the product that is used to produce this particular semi finished product. This functionality can also be used to create other raw material products, in which case the selected Production Type is product used (P-). When copying the information, the search key and name are suggested in the format [original product][operation name][operation line number], but can be overwritten with a different value. Any attributes related to the original product can be copied also.

Note:

Any changes to the automatically created product, such as unit of measure or cost type, can be updated in the Product screen.