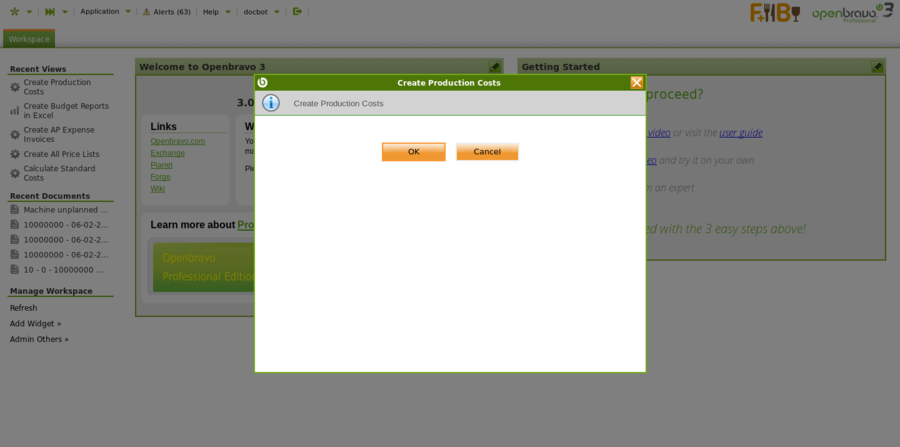

Create Production Costs

| Back to Production Management |

Introduction

Create Production Costs

| Starting from MP13 there is a new Cost Engine Available

This document belong to the legacy cost engine.

|

The Create Production Costs is run to generate the production (= real) cost. The application calculates the cost for each product based on the real time used in the cost center and the consumed materials per unit produced, as specified in the work effort. The cost of the employee, machine and indirect are the same as for the calculation of the standard cost, but are now multiplied by the actual use of the cost center and divided by the number of units produced.

The formula that is used by the process is the following:

(Cost of Cost Center, as indicated in the Work Effort + Cost Employees + Cost Machines + Indirect Costs) + (Quantity P- x Cost P-)/units produced on the work effort = the cost per unit.

When the costs of the cost center, machines, employees and indirect costs are calculated they are multiplied by different values depending of their unit of measure and divided by the number of units produced in the Work Effort:

If per Hour is used, the cost is multiplied by the Use of the cost center in the Process Plan and devided by the number of units produced

If per Unit is used, the cost is multiplied by the sum of the quantities of the P+'s of the sequence and divded by the number of units produced

If per Kilogram is used, the cost is multiplied by the sum of the weight of all the P+'s of the sequence and divided by the number of units produced

For Indirect costs the additional unit of measure percentage is available. This adds the defined percentage to the total cost calculated (cost center, employee, machine, indirect costs and P- products). For example if defined as 1.15, an additional 15% is added to the cost.

For raw material the average cost is used for the cost P-. If the operations of the Work Requirement are executed on separate Work Efforts, the operations production cost should be calculated after the Work Effort completion and set to Permanent in the Costing tab of the Product in order to be used as such in the calculation of follow up operations.

| Back to Production Management |